Description

For testing various full-field, live-load conditions, our PhotoStress® Technology stress analysis method is your ultimate tool.

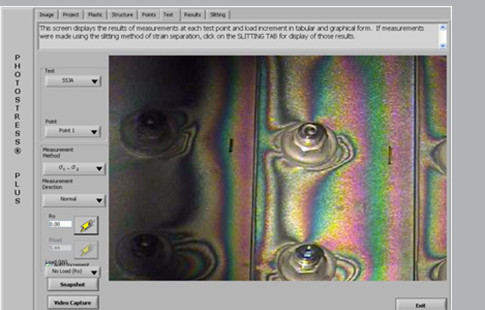

Determine stress and strain with a visual method employing photoelastic materials under polarized light. On your test surface, a colored fringe pattern appears, providing visual evidence of the magnitude and direction of strain at any point. In this PhotoStress® method, a coating of photoelastic material is applied to the test surface (a variety of photoelastic coatings are available for application on simple or complex shapes in a wide range of materials, including metal, composite, and concrete). Strain and stress are transmitted to the photoelastic coating on the product’s surface.

In addition to the versatile photoelastic coating, the PhotoStress® Analysis System includes a reflection polariscope and PSCalc® computer software that enables the user to store and process LF/Z-2 readings of stress and strain.

A Highly Effective Photoelastic Method for Stress Analysis

The PhotoStress® Analysis System is ideal for the following types of stress analysis:

- Stress resulting from fabrication tolerance

- Stresses related to the assembly process

- Fatigue stress

- Residual stress due to processes such as welding and casting

- Simple or complex stress analysis situations

The PhotoStress® Analysis System provides all of the following capabilities:

- Instant identification of stress concentrations and zero-stressed areas

- Qualitative measurement of stress and strain at any point on the structure

- Validation of any Finite Element Analysis (FEA)